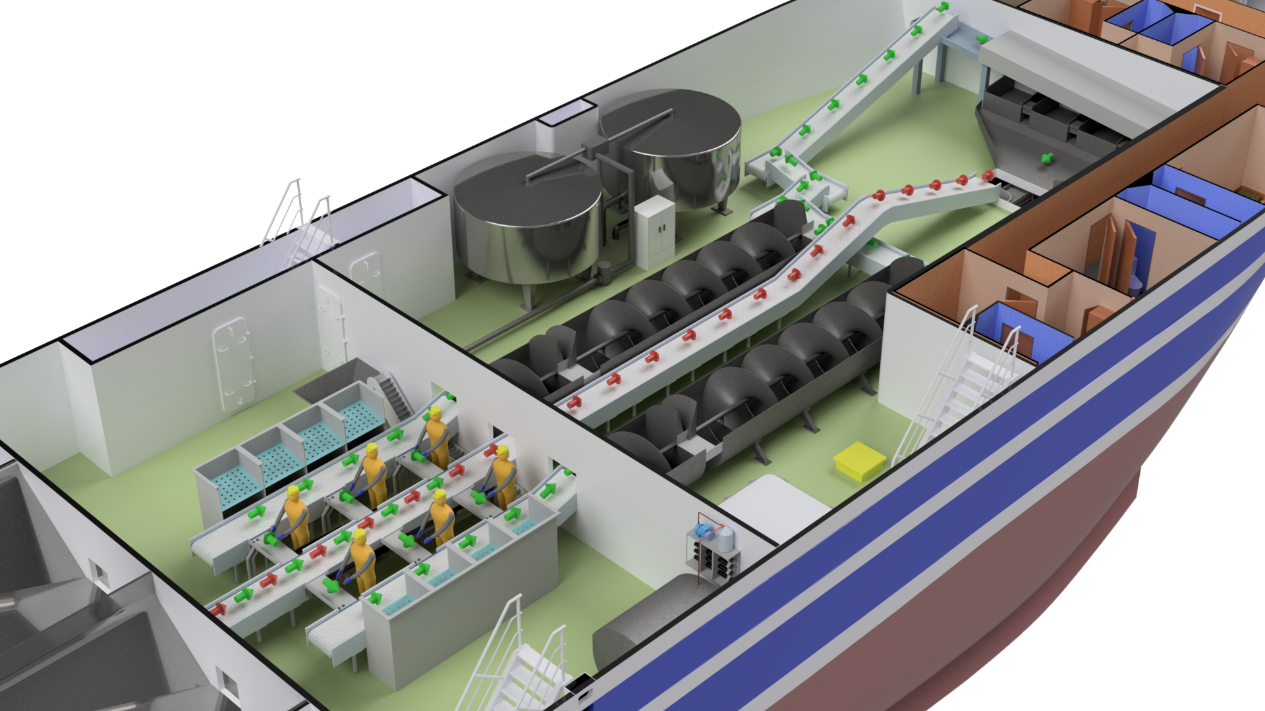

Large wetfish bottom trawlers

40-60 meter N-Atlantic (UK) fresh fish bottom trawlers

Main target catch

Activity

Fishing trip: 6-8 days

Average landings: 150-200 tons

Function

Benefits

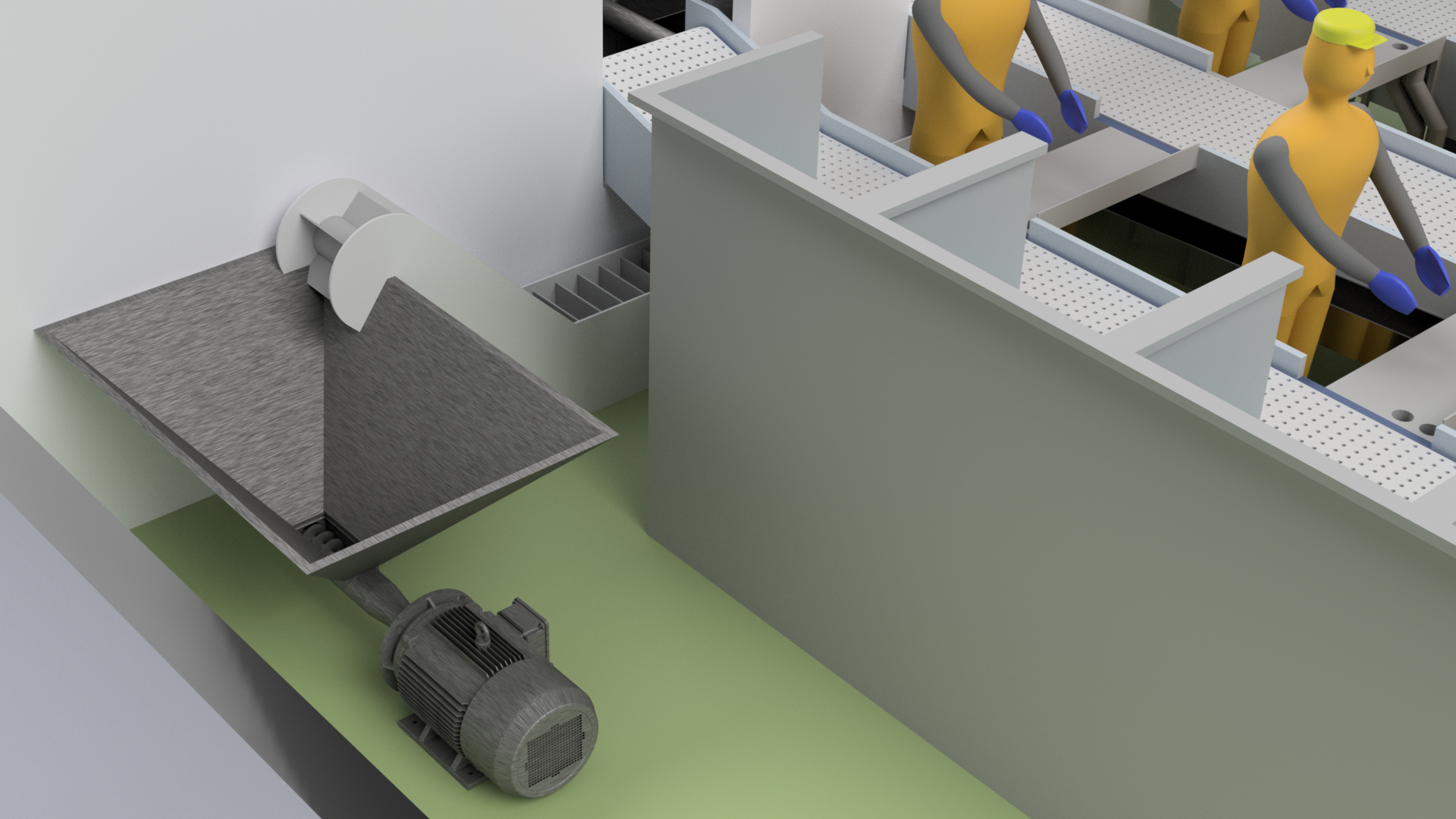

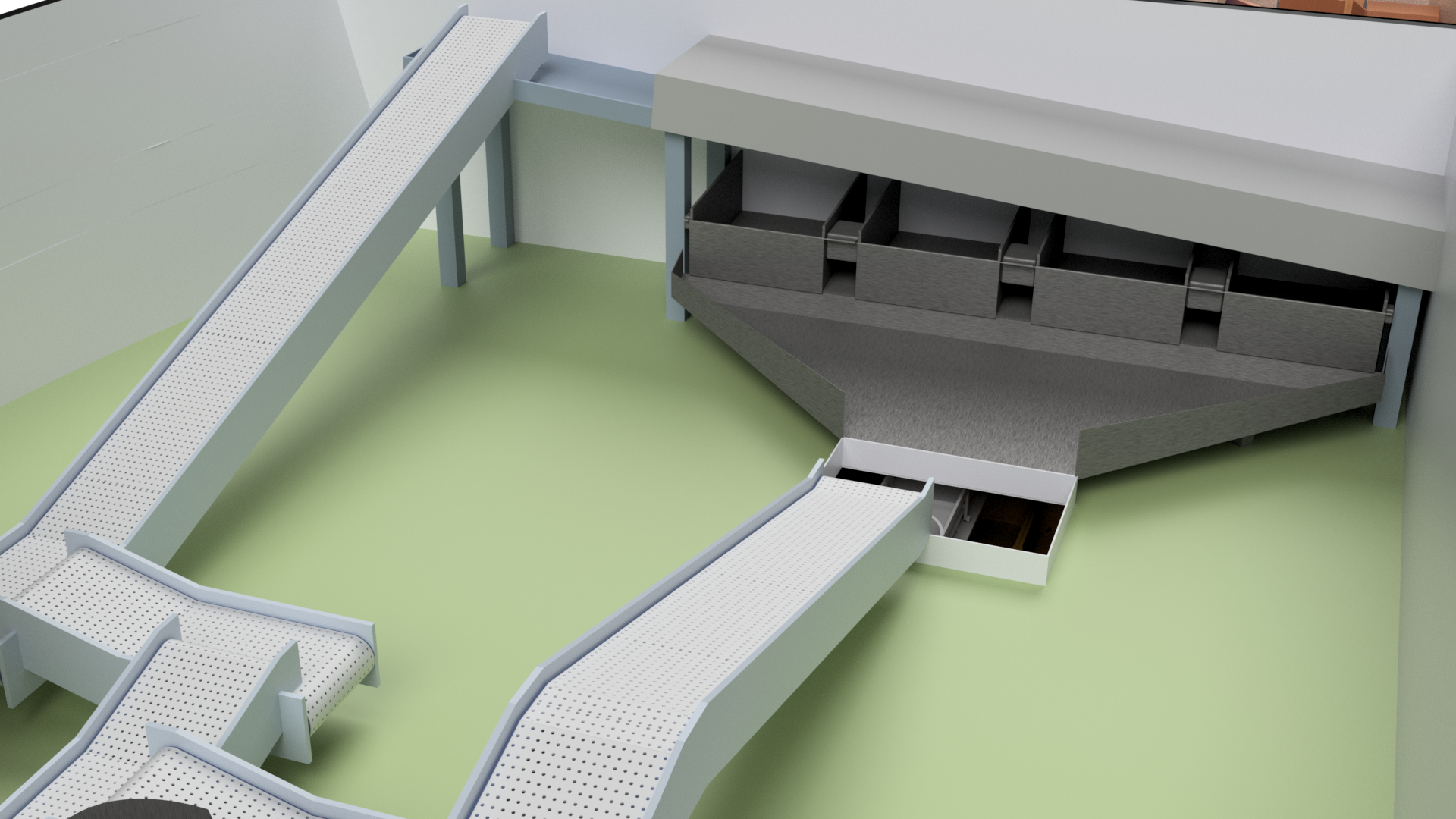

Reception : The fish is brought in from the reception by a controllable convoyor belt.

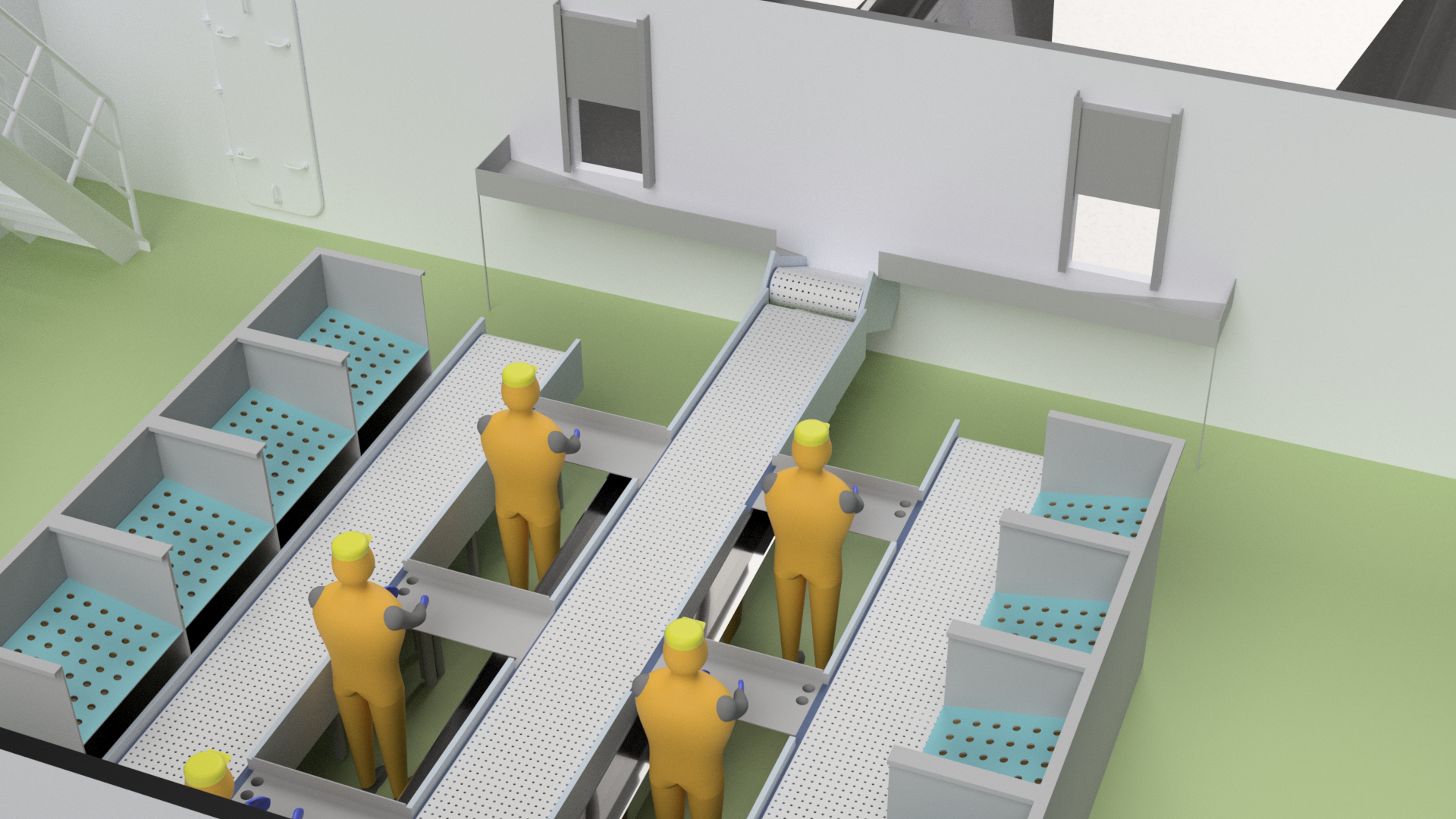

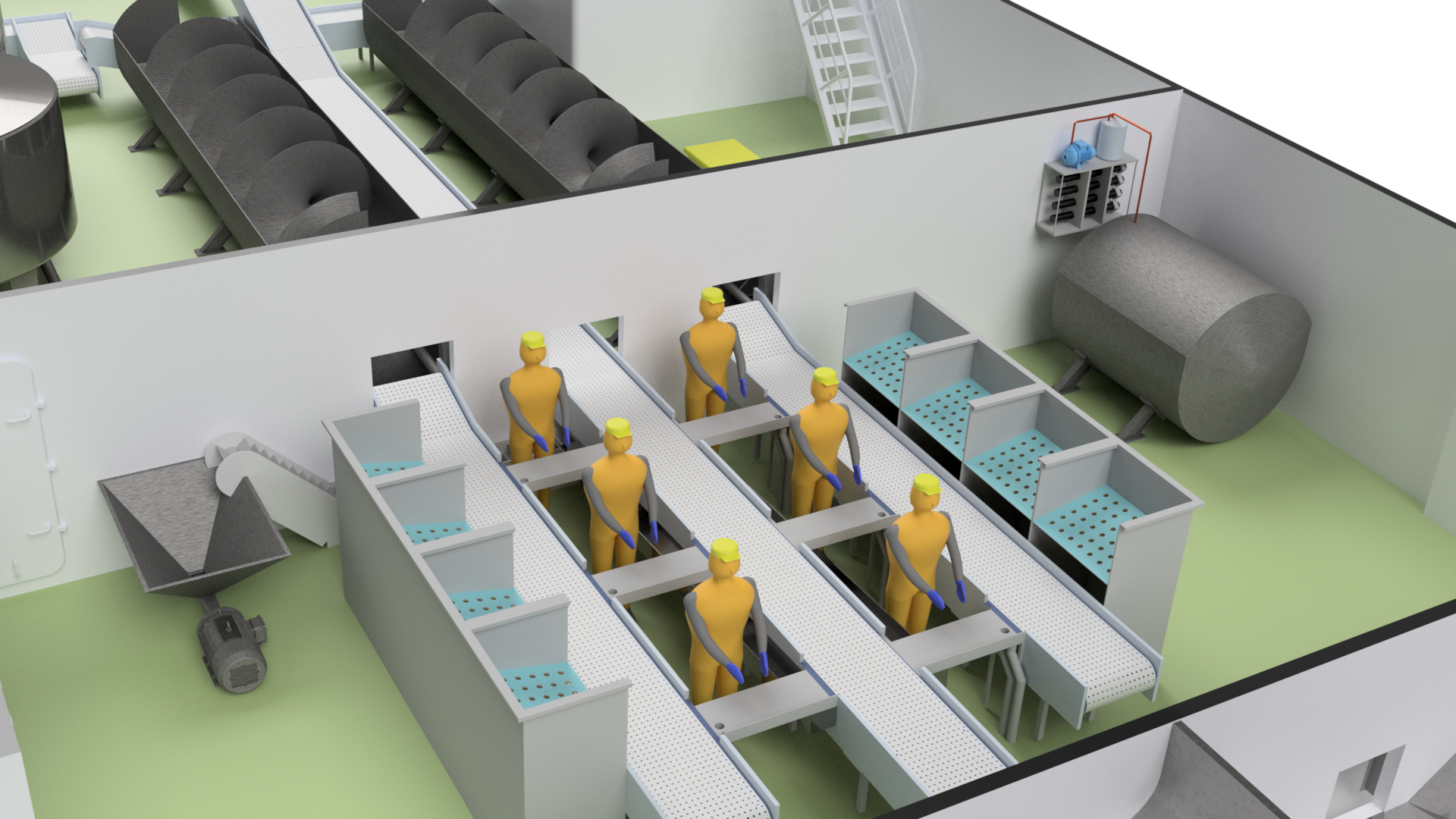

Bleeding/gutting station

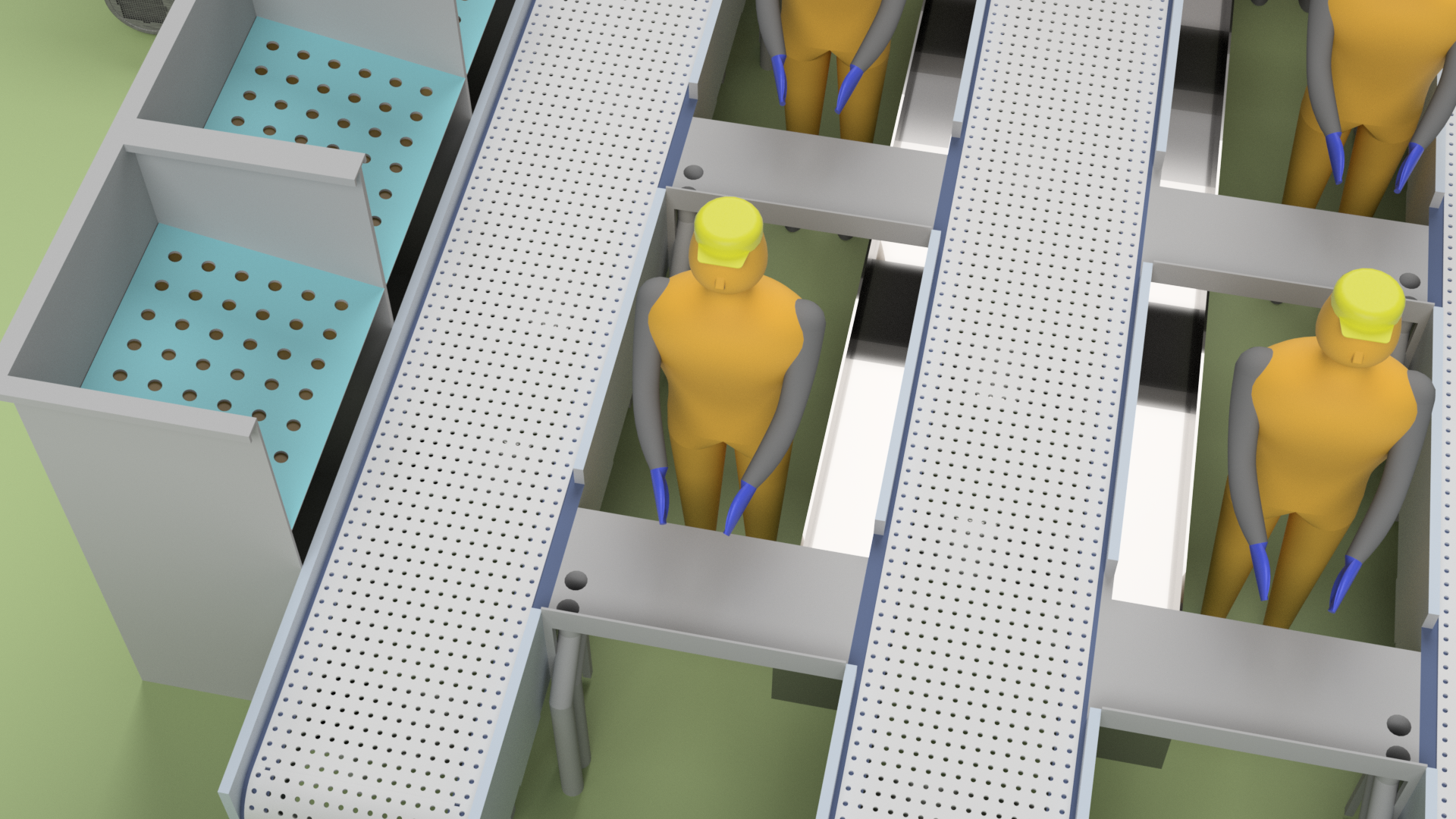

The fish is gutted prior to bleeding on the gutting station and viscera and offal's go into slides to a conveyor which feeds the material to the silage unit. UUC and fish under MCRS can also be sent to silage production or categorized into the sorting tubs.

The gutting board has holes in it for gathering of roe and liver and pipes that lead down to specific storage units in the hold

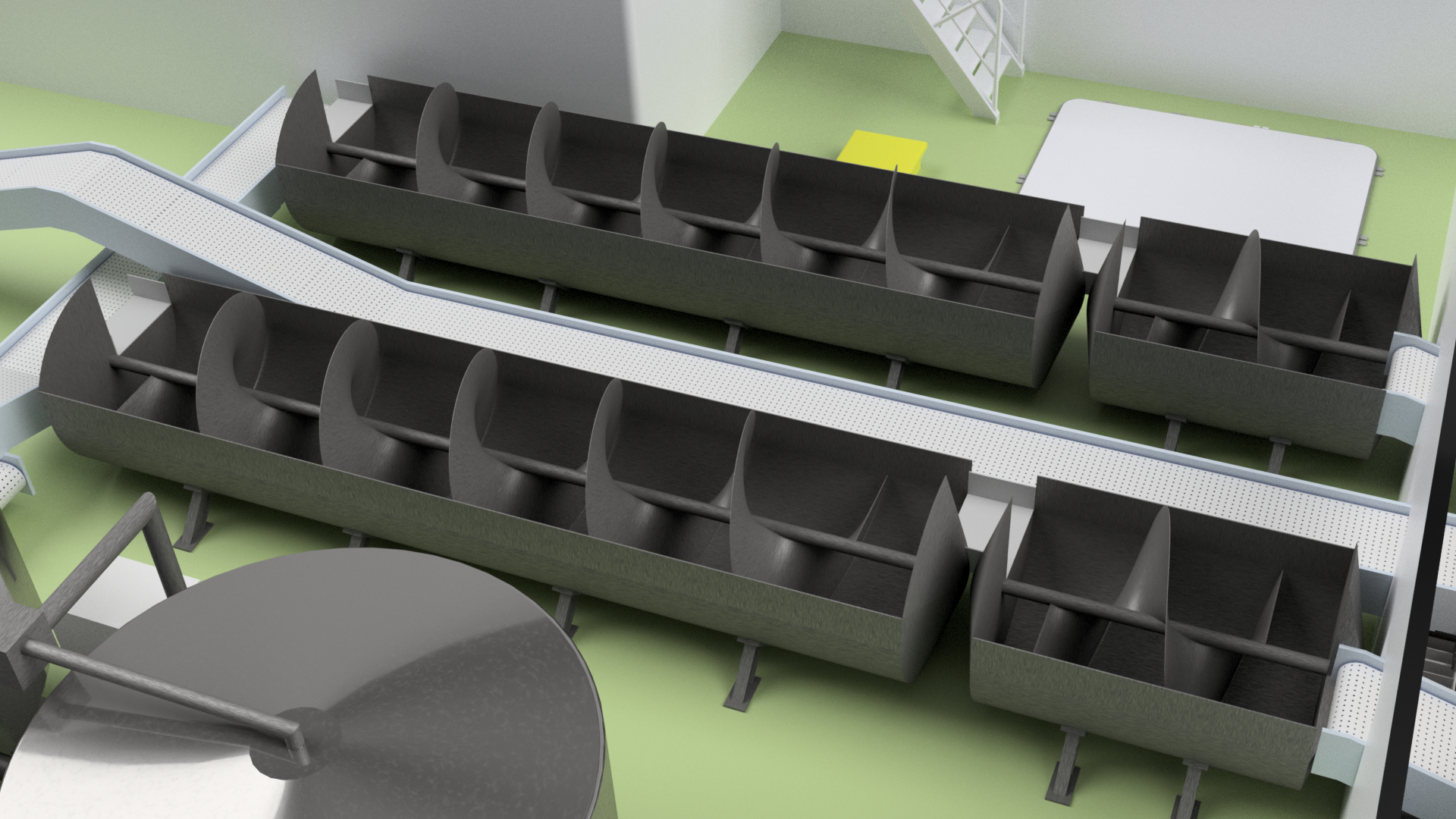

Sorting tubs: The sorting tubs are intentyed for sorting and temporary storing of fish under MCRS and UUC. When the main target species have been processed, the bottom of the tubs is elevated to bring the catch up ont the convoyor for the further processing.

Silage mincer The silage mincer receives viscera and possible UUC and fish under MCRS as well. The mincer shreds the material and feeds it forward with the help of a pump.

Slurry ice tank The tank serves as a buffer tank with slurry ice to ensure that there is enough ice for cooling at all times.

Bleeding and cooling tank Having separated bleeding and cooling tank promotes more effective bleeding and more hygiene conditions for the fish. It minimizes the risk of ice getting contaminated with blood and reduces renewal of slurry ice. The bleeding tank has circulation of seawater to get rid of blood and other impurities.

Sorting Each fish that goes through bleeding and cooling is transferred to a weighing station located at the front of the processing area. There, each fish is weighed and categorized into its respective category. For more sophisticated systems, additional species categorization could be implemented. When enough weight has been accumulated, a batch is released down to the cargo hold for storing and icing.

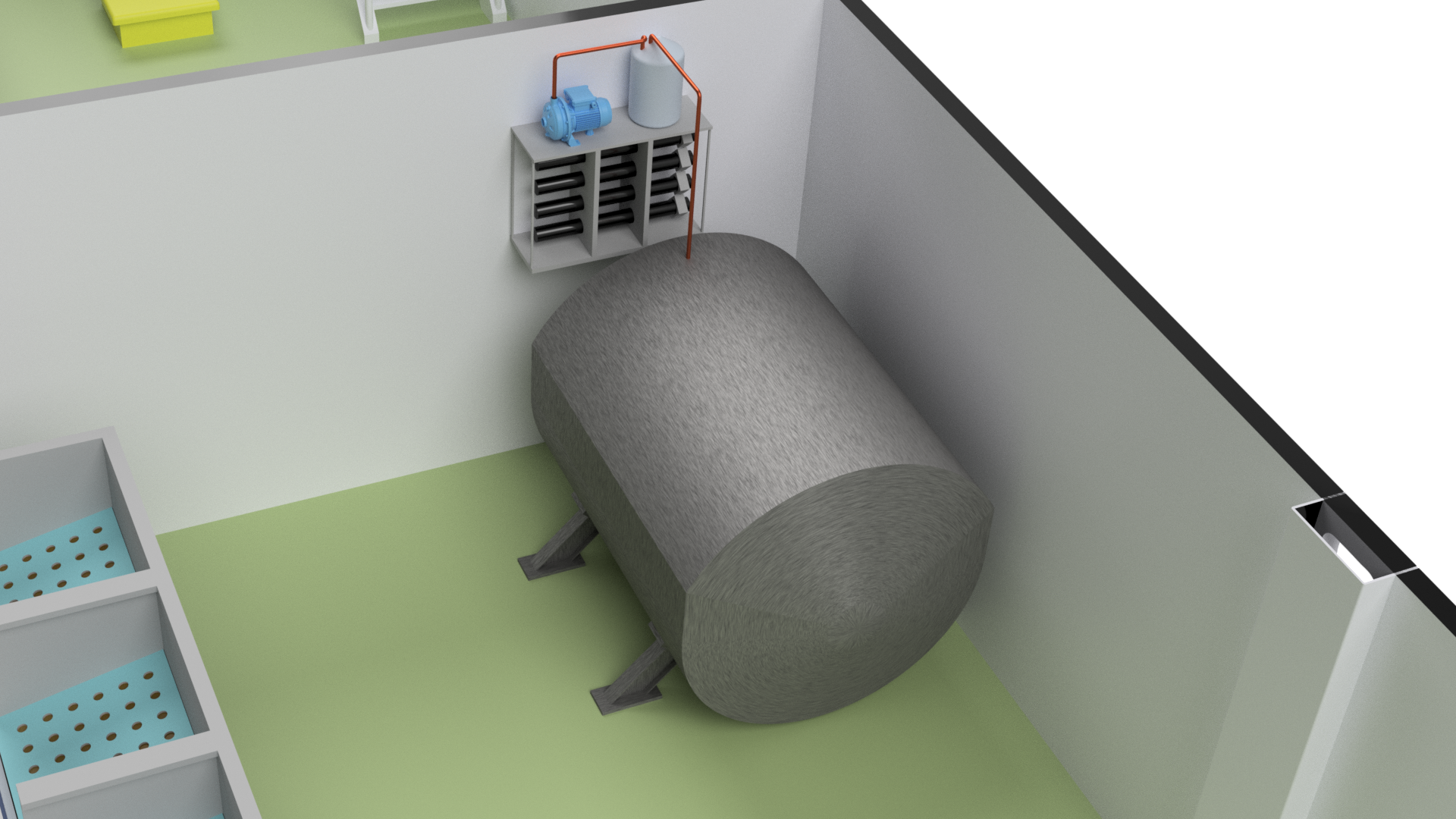

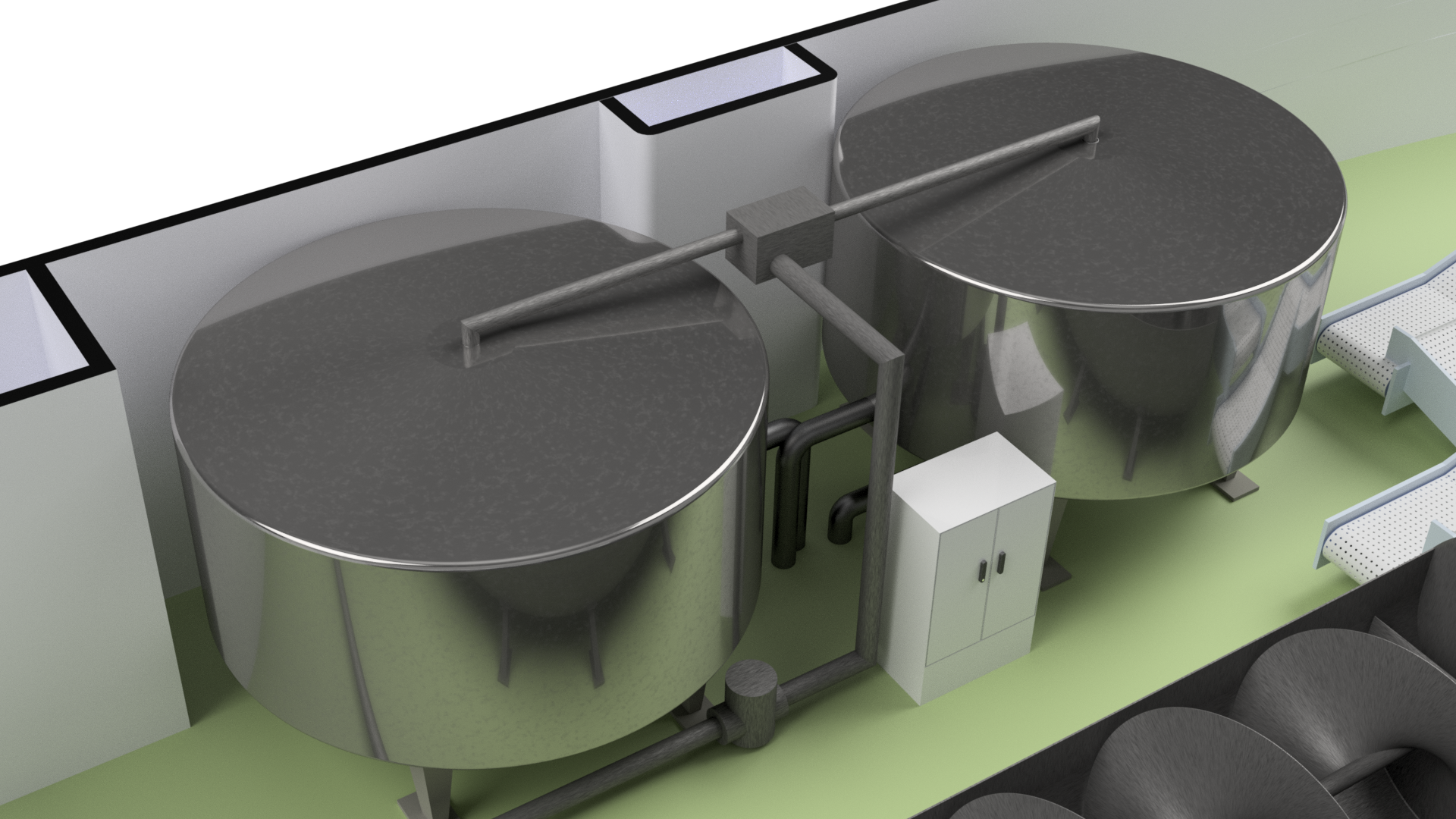

Pre-silage tank After mincing the raw material is pumped into day tanks where acid is mixed in proportions with the raw material. The material is heated up to 25-30 °C to speed up the digestion and to create more uniform product. It is also preferred to have pumps for constant circulation of the material to prevent settling of bones and other particles. After one approximately 24h the material is pumped down to the storage tanks.

Silage storage tank The storage tanks are in the front of the ship. There is plenty of alternatives available when it comes to construction of these tanks, but the simplest is to use large silos due to easy cleaning and maintaining. All the silage is gathered in these tanks and blended. This is possible due to the pre-digestion in the day tanks.

Download 3D PDF model

Citation :

Factsheet Large wetfish bottom trawlers, Author(s) : Birgir Sævarsson, Marvin Ingi Einarsson, Piotr Szymczak & Sigurður Örn Ragnarsson

Vioarsson, J. R., Ragnarsson, S. O., Einarsson, M. I., Saevarsson, B., Szymczak, P. (2017). DiscardLess WP5.4

Report on the 3D drawings and cost-benefit tools developed for Icelandic, North Sea and Bay of Biscay case studies.

http://www.discardless.eu/adapting_fishing_vessels